Modernization - Retrofits

RETROFIT OF MACHINE TOOLS allows you to economically maintain or improve the technical condition of a machine, that is almost destined due to its operation for its replacement, to achieve a very progressive extension of the machine's service life. We will propose a program to modernize your specific machine, focusing on efficiency and an economical solution for everyone.

Almost all types of machine tools that have a prospect of further use for the customer can be retrofitted. However, R.O.S.P specializes in horizontal boring machines from the TOS production and MAS MCV1000 milling centers.

The retrofitted machine is in the condition of a new machine with a higher added value than the original machine. Therefore, retrofitting cannot be viewed as a general overhaul.

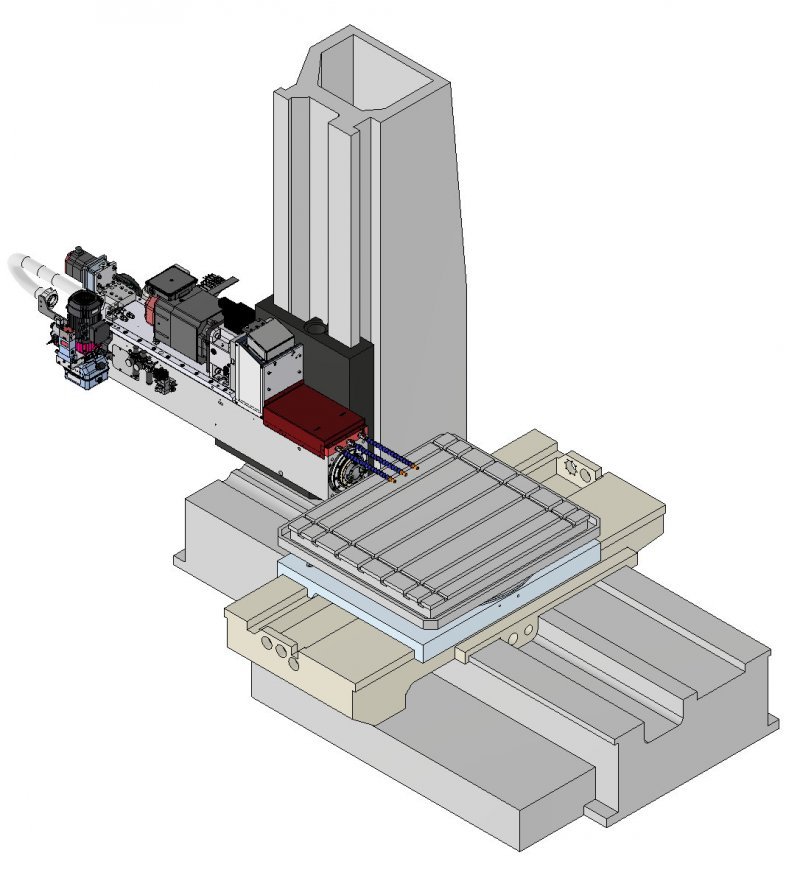

Modernization of WH10 horizontal boring machines to CNC

Retrofit of a classic, favorite, boring machine from the 80s produced by TOS Varnsdorf, into a fully controlled CNC machine in accordance with the modern concept of a horizontal boring machine, built on the original WH10 machine frame.

- full 5-axis CNC, Heidenhain TNC620 control system

- Heidenhain drives, Heidenhain QSY motors, Heidenhain measurement

- spindle 2500 rpm, ISO50, headstock cooled by refrigerator, Siemens spindle motor 21 kW

- table clamping area: 1000 x 1120 mm

- max. table load: 2000 kg

- XYZW travel: 1250/1100/900/540 mm

- rapid feed: 8000 mm/min.

- positioning accuracy: < 0.02 mm, according to the protocol

Customer: PONAS Polička 2008, TOOLS+ Zlivice 2012, Škoda Auto M.B., HS Machinenbau Hluboká nad Vltavou, Fostron Č.B., Pekon Strakonice 2018, Kromet Sp. Poland 2019, Bender & Hesse Fräs-und Bohrwerktechnik GmbH Germany 2019, Němec Žeranovice 2020, Zoko Tišnov 2020, FMS SK 2021, Mital DE 2022, Usinage Servitech inc. Canada 2023.

Modernization of WH10 horizontal boring machines in manual control

In 2024, R.O.S.P, in cooperation with FERMAT Pressl, embarked on the development of a small compact boring machine based on a new concept of a manually operated boring machine, the so-called mechatronic linkage. The machine is designed for piece production, repair operations, prototype production, or possibly for machining in heavy engineering, primarily as a future replacement for mechanically and morally obsolete conventional horizontals. It is a modern machine that meets the current requirements of working on a horizontal plane, has workshop cycles to speed up and facilitate work similar to CNC machines, but does not work in automatic mode, but only in manual mode. It is built on the proven skeleton of the WH10 horizontal machine.

- manual horizontal machine, the so-called mechatronics

- Fanuc drives, Fanuc motors

spindle 2000 rpm, ISO50, FERMAT headstock, Fanuc spindle motor 19 kW

- table clamping area: 1000 x 1120 mm

- max. table load: 2000 kg

- XYZW travel: 1250/1200/900/730 mm

- rapid feed: 2500 mm/min.

- positioning accuracy: < 0.02 mm, according to protocol

General repairs of horizontal boring machines W100A

General repairs of the legendary Vansdorf boring machine TOS W100A. The machine remains in its original, manual execution, minor modernization by installing Heidenhain Positip XYZB axis measurement and FAGOR / Heidenhain scales.

- general repairs of the skeleton and headstock

- new spindle, ISO50, new Argo-Hytos hydraulic tool clamping, speed control

- central lubrication distribution Tribotec

- new electrical, compact switchboard on the machine

- table clamping area: 1250 x1 250 mm

- max. table load: 3000 kg

- XYZW travel: 1600/1120/1250/900 mm

- positioning accuracy: < 0.02 mm, according to the protocol

Modernization of milling centers MAS MCV 1000

Retrofit of the well-known 3-axis milling center produced by MAS Kovosvit Sezimovo Usti. The 1st generation machines, known for their rigidity and durability, are now at the end of their service life. We are converting these machines into modern machining centers using components from renowned manufacturers, using the skeleton of the original machine.

- general overhaul of the skeleton and headstock

- new spindle, ISO40, new tool clamping

- Heidenhain TNC620 control system, touch screen, Heidenhain drives, Heidenhain motors, Heidenhain rulers

central distribution of Tribotec / Dropsa oil lubrication

- new electrical, compact switchboard on the machine

- table clamping area: 1300 x 600 mm

- max. table load: 700 kg

- XYZ travel: 1000/600/660 mm

- accuracy of positioning: < 0.01 mm, according to the protocol

Project Gallery

FERMAT CZ