Machine tool servicing and repairs

We provide comprehensive machine tool servicing in the event of breakdowns, accidents, but also as part of routine or regular maintenance. We stock spare parts for machines that we routinely make, and we can provide or manufacture them for old machines.

We are flexible in urgent interventions, in multi-shift operations, after accidents etc.

- comprehensive servicing / repairs of horizontal boring machines DIXI, TOS W100, WH10, WHN9, MAS WXH100

- comprehensive servicing / repairs of coordinate boring machines souřadnicových vyvrtávaček MAS WKV100, SIP, Mikromat

- comprehensive servicing / repairs of milling centers MAS MCV

- comprehensive servicing / repairs of lathes TOS SV18RA, SV18RD, MAS Masturn MT

- repairs of geometry

assistance with installations, relocation, etc.

Measurement of machine geometry

Measuring the geometric accuracy of machines and precise positioning of coordinates with the possibility of analysis, evaluation of inclinations and deformations, insert of new corrections into CNC systems. These measurements are carried out with a Renishaw laser interferometer, where high accuracy and reliability of measured data are maintained. Evaluation is carried out with Renishaw software.

The heart of your CNC control system is still free of defects, but your machine is mechanically worn out, which leads to significant inaccuracies in production. Using the modular Renishaw measuring device and Renishaw software, they measure and analyze deviations in the positioning of machine tool coordinates. They evaluate and transfer corrections to the CNC control system. We measure and evaluate the parallelism, straightness and mutual inclinations of the machine's working axes, the flatness of the machine's working surfaces, measuring plates with the possibility of scraping. Evaluation is in ISO 230-2, VDI / DGQ 3441, ČSN 200300 standards.

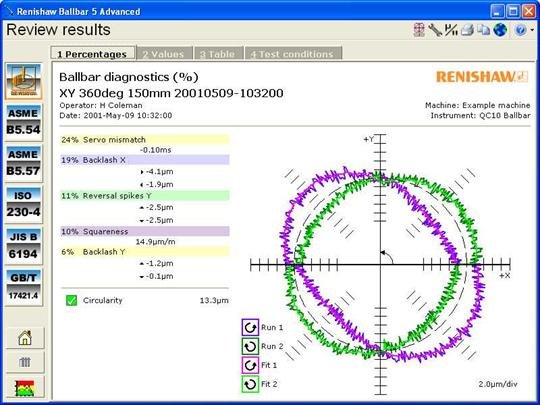

Diagnostics with the QC 10 calibration system

The quality of individual parts produced on a CNC machine is primarily dependent on the accuracy of the machine tool. Mechanically worn parts of the machine itself and poor geometry of individual parts inevitably lead to significant inaccuracies in production, downtime and high scrap rates. Based on a good analysis, the accuracy of the machine is often increased only by corrections in the machine tool control system. Long-term insufficient product quality must be solved and it is necessary to carry out analysis of possible errors that are the likely cause.

- tool errors

- errors in drawings

- errors in inspection

- NC software errors

- errors in the machine operator itself

The analysis of errors that could cause inaccuracies detected by quality control requires a lot of time. This results in a decrease in productivity, or even the machine shutdown and the cessation of work on the given product until the causes are eliminated.

Service of spindles

The spindle, or rather the headstock, is one of the most important, most complicated and most expensive components of any machine tool. The spindle bearing is a part of the machine mechanics that usually has one of the largest number of operating hours of the entire machine tool. Their condition has a direct impact on the quality of machining, vibrations, tool life, noise.

R.O.S.P has the technical background and knowledge to repair almost all possible spindles / headstocks of milling, turning, grinding machines of most renowned manufacturers. We manufacture completely new spindles for the WH10, W100A, MCV1000, MCV1016, BPH20NA machines in-house, including new clamps and all hardware. We are able to repair spindles after serious accidents, collisions during tool changes, rust from leaking rotary connections etc.

- bearing replacement, steel, ceramic, hybrid bearings, including special spindle types

- repair / production / replacement of damaged parts, rings, bodies, houses, rotary connections

- production of new spindles

- rewinding of electrospindles, repairs of cables, sensors, encoders

- comprehensive repairs after accidents, flooding, as part of routine maintenance

- vibration diagnostics

- balancing with the ADASH A4300 device

- regrinding of conical cavities (cooperatively and without dismantling from the machine)

- complete regrinding of spindles, repairs of seized diameters

- on MAS MCV 750/754/1000/1016 (ISO40) machines, it is possible to replace them by return, including installation

- service interventions, medium repairs, general repairs of headstocks W100A, HP100, WH10, WKV100, WXH100, BPH20NA, SV18RA/RD, SUI, MAS Masturn MT

- rebuilding of WH10 headstocks to 2500-3000 rpm with external cooling of the housing by a refrigerator

- repairs of WKV100 headstocks gearboxes, from timing adjustment to general overhaul

Service of electrical

The department of Electrical Service offers services in the field of HW/SW service for Heidenhain / Fanuc control systems.

These services can be summarized in the following points:

- diagnosis of control system faults

- optimization of machine drive settings

- version upgrades, user's modifications of SW and PLC

- replacement of HDD, SSD batteries

- setting corrections from the laser interferometer

- technical proposals for electrical modernization, feasibility studies

- providing spare parts, HW repairs

FERMAT CZ